|

Water Glass Casting

|

|

Water glass casting is also called Cryogenic lost wax casting. The dimension tolerance of water glass casting we could reach is ISO 8062 CT7-8.The main material of water glass casting is Carbon steel, Alloy steel,Dutile Iron, Hight Cr Cast Iron, Gray Iron, Resistance cast iron.And the weight of water glass casting controled is about 0.3-100kg.

|

|

Water Glass Casting Process

|

|

|

|

Strictly making 3D model based on customer’s drawing dimensions, and mastered the contractibility rate for all types of material.

|

|

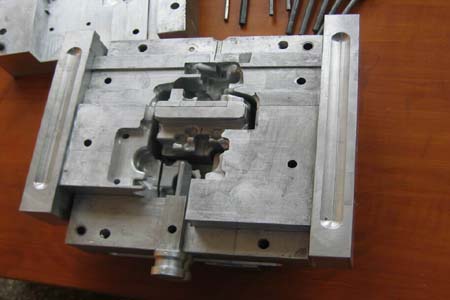

2. Wax Injection

Wax design of the desired castings are produced by injection molding. These

|

designs are called patterns.

|

|

|

3. Assembly

The patterns are attached to a central wax stick, called a sprue, to form a casting cluster or assembly.

|

|

4. ShellBuilding

The shell is built by immersing the assembly in a liquid ceramic slurry and then into

|

a bed of extremely fine sand. Up to eight layers may be applied in this manner.

|

|

|

5. Dewax

At this point, all of the residual pattern and gating material is removed, and the ceramic mold remains. The mold is then preheated to a specific temperature and filled with molten metal, creating the metal casting.

|

This process is to put the lost-wax shell into the roast furnace and make them harder. Heating the Mould shell before casting is also to ensure the better products surface texture.

|

|

|

|

7. Smelting the Liquid Steel

Allocate the chemical composition and sampling before steel casting.

|

|

8.Spectrochemistry Analysis

Inspection on materials by spectrometer testing.

|

|

|

9. Conventional Casting

In the conventional process, the shell is filled with molten metal by gravity pouring.

|

10. Cut Off

The parts are cut away from the central sprue using a high speed friction saw.

|

|

|

|

Carbon steel and low-alloy steel need normalizing and temper, oil-quenching, water-quenching and so on. We can set out different heat treatment method as per different requirement from customers.

|

|

Polishing is to modify the out of flatness on casting head after casting cuttig and to modify the burring and splashing in the process of casting cycle.

|

|

|

|

|

Inspection of the mechanical properties, surface, internal quality, and to check if the rough dimension meet the drawing requirement for the prodcuts.

|

Cut the piece of raw material into a desired final shape and size. Now we have CNC, Lathe, milling machine, drilling machine, boring lathe and grinding machine.

|

|

|

|

Quality inspection on the machining dimension. Mainly tools we use is like specialized gauge and callipers, mircocalliper,three-dimensional and so on.

|

Efficiency of package goods delivery on time per your shipping requests.

|

|

Advantage of water glass casting

|

|

Wide Application Scope

Our water glass casting process is virtually unrestricted by the size ,thickness and shape complexity.

Wide Choice of Alloys

Our water glass casting process able to utilize a wide variety of alloys for common carbon steel, alloy steel, manganese steel,stainless steel ,and high-Cr & wear-resist Iron and so on.

Dimensional Accuracy

The water glass casting process is capable of producing foundry with higher accuracy than ordinary forgings and weld assembly in general condition.

Reduction of Production Costs

Water glass castings are able to reduce costs in many cases such as reduced machining, less materiel waste and so on.

|

In addition, we own CNC machining center and CNC Lathe, so machine parts (machining parts or machinery parts),metalwork (metal products) are ok for us!

|