|

Carbon steel casting

|

The carbon steel casting is a casting which uses the carbon steel casting parts and other materials to mold. The carbon steel is composed of large number of carbon, small amounts of silicon, manganese, sulfur, phosphorus and other impurities.

According to the level of carbon content in the carbon steel casting, carbon steel can be divided into low carbon steel, medium carbon steel and high carbon steel. Which one's carbon content is less than 0.25% is known as low-carbon steel. In the range of 0.25-0.6% is medium carbon steel. More than 0.6% is called high-carbon steel.The content of carbon plays the important role in the quality of the products in carbon steel casting.

|

|

Carbon Steel Casting Process

|

|

|

|

1. Mould Designing

Strictly making 3D model based on customer’s drawing dimensions, and mastered the contractibility rate for all types of material.

|

2. Wax Injection

Wax design of the desired castings are produced by injection molding. These

designs are called patterns.

|

|

|

3. Assembly

The patterns are attached to a central wax stick, called a sprue, to form a casting cluster or assembly.

|

4. Shell Building

The shell is built by immersing the assembly in a liquid ceramic slurry and then into a bed of extremely fine sand. Up to eight layers may be applied in this manner.

|

|

|

5. Dewax

At this point, all of the residual pattern and gating material is removed, and the ceramic mold remains. The mold is then preheated to a specific temperature and filled with molten metal, creating the metal casting

|

6. Mould Shell Roast

This process is to put the lost-wax shell into the roast furnace and make them harder. Heating the Mould shell before casting is also to ensure the better products surface texture.

|

|

|

7. Smelting the Liquid Steel

Allocate the chemical composition and sampling before steel casting.

|

8.Spectrochemistry Analysis

Inspection on materials by spectrometer testing.

|

|

|

9. Conventional Casting

In the conventional process, the shell is filled with molten metal by gravity pouring.

|

10. Cut Off

The parts are cut away from the central sprue using a high speed friction saw.

|

|

|

11.Heat Treating

Carbon steel and low-alloy steel need normalizing and temper, oil-quenching, water-quenching and so on. We can set out different heat treatment method as per different requirement from customers.

|

12. Polishing

Polishing is to modify the out of flatness on casting head after casting cuttig and to modify the burring and splashings in the process of casting cycle.

|

|

|

13. Inspection:

Inspection of the mechanical properties, surface, internal quality, and to check if the rough dimension meet the drawing requirement for the prodcuts.

|

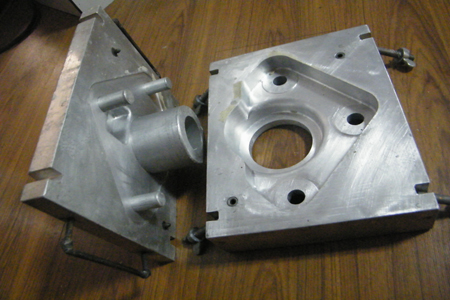

14. Machining

Cut the piece of raw material into a desired final shape and size. Now we have CNC, Lathe, milling machine, drilling machine, boring lathe and grinding machine.

|

|

|

15.Quality Inspection:

Quality inspection on the machining dimension. Mainly tools we use is like specialized gauge and callipers, mircocalliper,three-dimensional and so on.

|

16. Storage and Delivery

Efficiency of package goods delivery on time per your shipping requests.

|

|

Emphasis on quality control in steel casting:

|

|

1.The make of technology research recording card:

We can assure there will be no any holes, blister, crack, shrinkage cavity and so on based on technology. We will do some records about the easy-making mistake during the products development and note the correct operation methods.

2.Wax Mould sampling and Dimension inspection:

This process is to avoid changing of wax pattern contractibility rate results from the temperature change in the wax-pattern workshop, and finally result in products dimension disqualification. The rectification measure includes: Adjusts the temperature at the wax injection workshop and the water temperature used in Wax pattern cooling; testing tools; Callipers; Microcalliper;inner diameter gauge and Hight gauge.

3.Molten steel temperature control:

Investment casting differs from sand casting, Casting temperature need to be controlled perfectly, low temperature will result in incomplete products casting and have lack of body on the products;Excessive High-temperature will results in crack on the products. We install temperature inductor by the furnace and ask workers do temperature recording when casting, for the aim of better control the temperature.

4.Molten steel chemical composition control:

our company owns advanced Spectrograph imported from Germany to assure that the products chemical composition conformed with specified standards. We will also test the molten steel composition before products casting, simultaneously, molten steel after casting will be sampled for Spectrograph testing, guide sample after casting will be kept for 2 years and also can keep as per customer’s requirement.

5. Products heat treatment control:

Correct heat treatment process is the only way to assure the products mechanical properties. We will design the heat treatment technology as per the products chemical composition and mechanical properties standards and provide the heat treatment process reports and temperature recording reports according to customer’s requirements.Also we can provide customer products testing bar in the same heat treatment furnace for customer inspection.

6.Products surface quality and dimensional inspection:

We have passed ISO:9000 certificate, and own special quality inspection department. With different products, quality inspection department will design different fixture and gauge. We will do 100% inspection upon the products for quarantee unqualified products scrapped in our company.

|